Some specialized model makers combine advanced CAD capabilities, 3‑ and 5‑axis CNC manufacturing, and traditional craftsmanship to produce large‑scale models for the amusement and entertainment industry, as well as for artists, designers, and exhibition professionals.

Their work spans a wide range of applications: competition rowing boats, components for water parks, theatrical, concert, and film sets, exhibition mock‑ups for corporate events, and artistic installations for restaurants and clubs. Architectural elements and decorative structures also fall within this field.

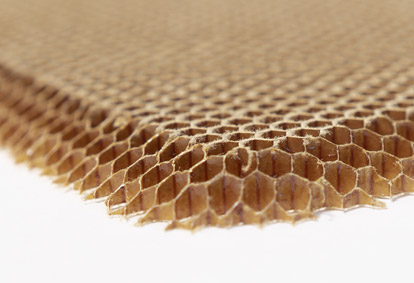

For these projects, medium‑ to large‑format 5‑axis CNC machines are typically used to mill molds and plugs from materials such as wood, EPS, epoxy, or PU tooling boards. Composite materials—including fiberglass, resins, and other polymer‑based coatings—can also be machined to achieve excellent surface quality.

At Multiax, we bring extensive experience to these processes. We support companies not only by supplying high‑performance composite CNC routers (particularly FRP CNC routers and carbon fiber CNC machines), but also by advising on the most profitable technology configurations and best practices to maximize productivity and quality.