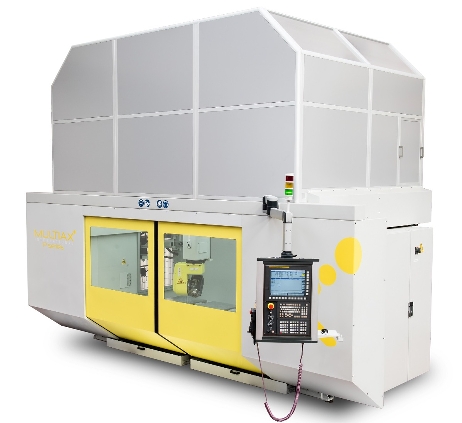

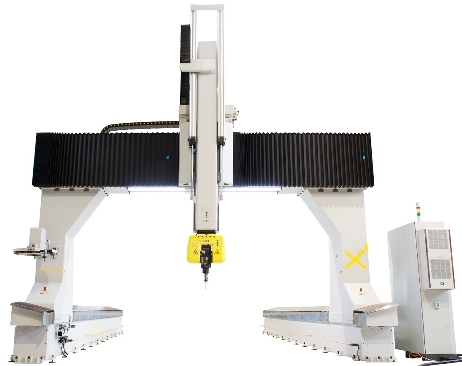

Boat builders rely on a wide range of precision processes, from model and pattern making to the cutting and trimming of complete hulls, decks, and structural components. Our CNC solutions are engineered to elevate every stage of this workflow. Multiax shipbuilding CNC machines deliver outstanding productivity, consistent repeatability, and enhanced operator safety — all essential for modern marine manufacturing.

One of the most common challenges in the sector is the integration of CAD/CAM workflows. Multiax addresses this with advanced, user‑friendly solutions that significantly reduce setup times, optimize machining cycles, and boost overall productivity. The result is a smoother, more efficient transition from digital design to finished component.

For decades, we have supplied a wide variety of marine CNC machines to shipyards and boatbuilders worldwide, accumulating a deep understanding of the sector’s unique needs. This experience drives our commitment to innovation — going far beyond traditional CNC milling. By leveraging the typically large dimensions of marine components, we design systems that automate operations historically performed by hand, improving process consistency and creating measurable added value.

Multiax acts as a complete, long‑term partner for marine manufacturers. Our team supports customers from the earliest stages — recommending the ideal CNC configuration to match performance expectations — through installation, commissioning, and beyond. We also provide comprehensive training and consulting, helping operators master advanced functions and adopt best practices that unlock higher productivity and superior machining results.

With Multiax, boatbuilders gain not just a boat CNC machine, but a strategic advantage: technology, expertise, and support that empower them to build faster, safer, and with uncompromising quality.