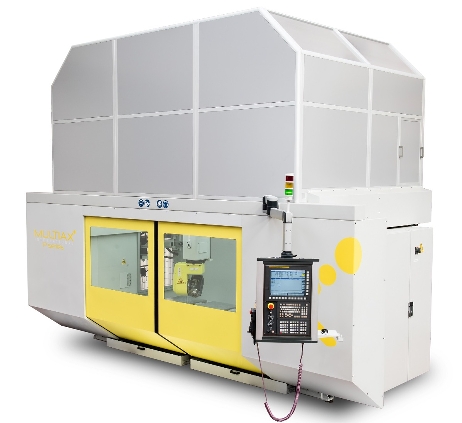

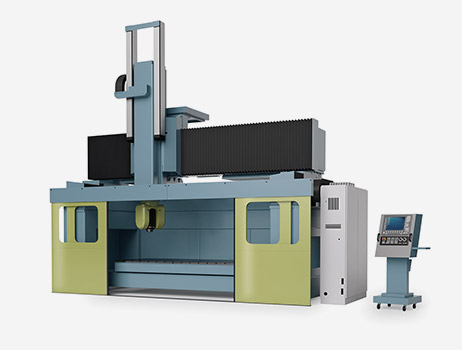

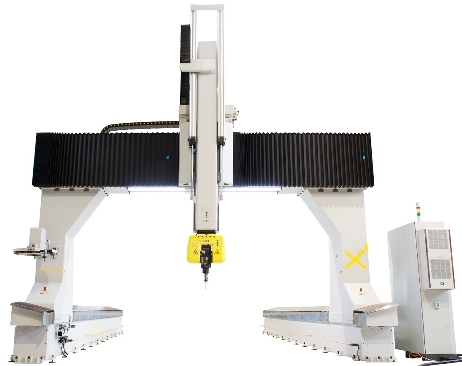

We supply a broad range of CNC solutions tailored to the diverse processes of the automotive industry, supporting different materials, production methods, and performance requirements. Our customers use Multiax systems for activities such as:

- Full‑scale (1:1) molds and mock‑ups in prototype departments, using advanced material CNC routers

- Machining of complex 3D components, using aluminum CNC Routers for structural or interior parts and composite elements

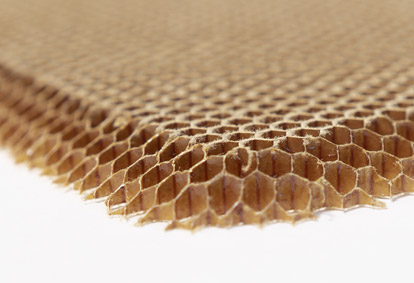

- Manufacturing of components for ground mass transportation and the rail industry, using aluminum CNC Machines for structural parts, plymetal flooring, side‑wall interior panels, ceiling panels, honeycomb cores, windshield panels, engineer cab doors, cab partitions, and doors

For these applications, medium‑ to large‑format 5‑axis automotive CNC machines are typically employed to mill molds and plugs from wood, EPS, epoxy, or PU tooling boards. Composite materials—such as fiberglass, resins, and other polymer‑based coatings—can also be machined to achieve high‑quality surface finishes.

At Multiax, we combine extensive industry expertise with advanced engineering. We support customers not only by providing high‑performance CNC systems, but also by advising on the most profitable technology configurations and best practices to maximize efficiency, precision, and return on investment.